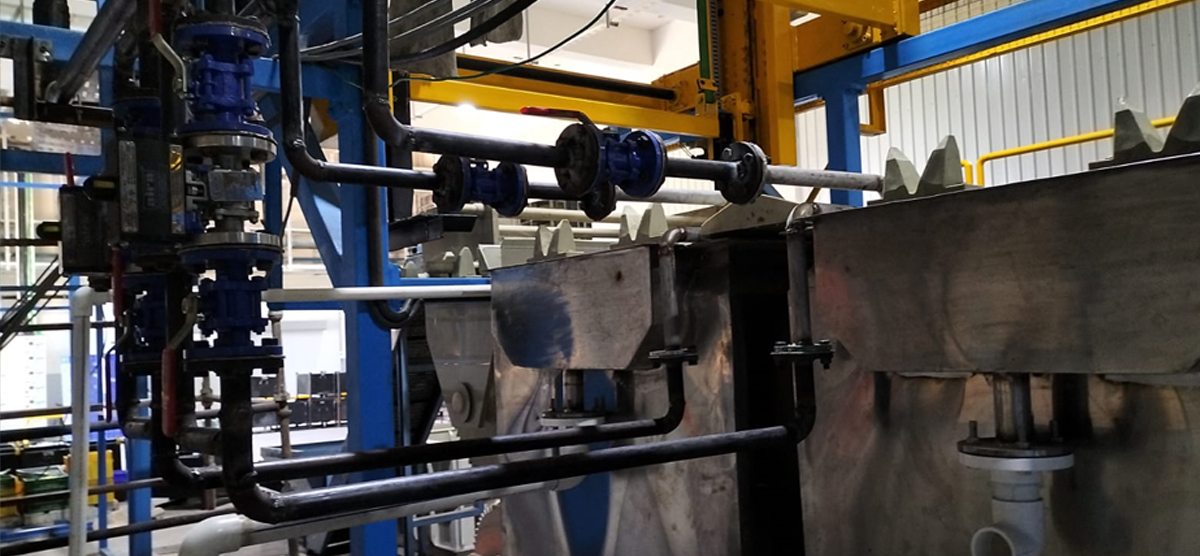

Electro Plating Plants

Electroplating plants are vital in various industries, enhancing the durability and aesthetics of metal products. Employing advanced techniques, these plants create a protective coating on surfaces, preventing corrosion and enhancing conductivity. From automotive parts to intricate electronics, electroplating plays a crucial role in delivering high-quality, resilient finishes across diverse applications.

Zinc plating plant

A Zinc plating plant is an industrial facility specializing in the application of zinc coatings to metal surfaces through electroplating processes. These plants play a pivotal role in enhancing corrosion resistance and providing a durable finish to a wide array of products, ranging from automotive components to hardware. Utilizing cutting-edge technology, Zinc plating plants contribute to the longevity and aesthetic appeal of metal goods in various industries.

Nickel-Chrome plating plant

A Nickel-Chrome plating plant is an advanced facility dedicated to electroplating processes, applying layers of nickel and chromium onto metal surfaces. This dual-layer coating enhances corrosion resistance, durability, and aesthetic appeal. Commonly utilized in automotive, aerospace, and decorative applications, Nickel-Chrome plating plants ensure a high-quality finish that meets stringent industry standards for both functionality and visual appeal.

Abs plating plant

An ABS plating plant is an essential facility specializing in electroplating processes for Acrylonitrile Butadiene Styrene (ABS) plastic components. This plant enhances the surface properties of ABS materials, providing durability, corrosion resistance, and an attractive finish. Commonly employed in automotive and electronics industries, ABS plating plants contribute to the production of high-quality, resilient plastic parts with improved functionality and aesthetics

Hard chrome plating plant

A Hard Chrome plating plant is a specialized facility focused on electroplating processes to apply a layer of hard chrome onto metal surfaces. This robust coating enhances wear resistance, durability, and corrosion protection. Essential in industries like manufacturing and engineering, Hard Chrome plating plants contribute to the production of components that withstand harsh conditions while maintaining a sleek and polished appearance.

Tin plating plant

A Tin plating plant is a facility specializing in electroplating processes to apply a layer of tin onto metal surfaces. This coating enhances corrosion resistance, solderability, and provides an attractive finish. Widely used in the production of electronics, Tin plating plants contribute to manufacturing components with improved conductivity and durability, crucial in various industrial applications.

Silver plating plant

A Silver plating plant is a specialized facility employing electroplating techniques to apply a layer of silver onto metal surfaces. This process enhances conductivity, corrosion resistance, and imparts a lustrous finish. Commonly utilized in the production of high-end electronics, decorative items, and tableware, Silver plating plants contribute to the creation of aesthetically pleasing and functionally superior products.

Electroless nickel plating plant

An Electroless Nickel Plating Plant is a sophisticated facility specializing in a unique electroless plating process, depositing a uniform layer of nickel on various surfaces without the need for an external electrical current. Renowned for its even coverage, corrosion resistance, and wear durability, Electroless Nickel Plating finds extensive use in aerospace, automotive, and electronic industries. This plant ensures precision and reliability in providing exceptional protective coatings on a variety of materials.

Anodizing plating plant

An Anodizing Plating Plant is a specialized facility focused on the electrochemical process of anodization, enhancing the surface of metals, especially aluminum. This plant creates an oxide layer, improving corrosion resistance, durability, and providing an array of vibrant colors for decorative purposes. Widely used in aerospace, automotive, and architectural applications, Anodizing Plating Plants contribute to the production of high-performance and visually appealing metal components.

Electro-polishing plant

An Electro-polishing Plant is an advanced facility specializing in the electrochemical process of removing microscopic surface irregularities from metal objects, leaving them polished and smooth. This technique enhances corrosion resistance, improves cleanliness, and imparts a sleek finish. Commonly applied in industries such as pharmaceuticals, electronics, and aerospace, Electro-polishing plants play a pivotal role in producing high-quality, precision-engineered metal components with superior surface characteristics.

Copper plating plant

A Copper Plating Plant is a specialized facility utilizing electroplating processes to apply a layer of copper onto metal surfaces. This enhances conductivity, corrosion resistance, and provides an attractive finish. Commonly used in electronics, telecommunications, and decorative applications, Copper Plating Plants contribute to the production of components with improved functionality and aesthetic appeal. The process ensures a uniform coating, making it vital for various industrial applications.

Lacquer plating plant

A Lacquer Plating Plant is a specialized facility employing a process that involves coating metal surfaces with lacquer, a protective layer that enhances durability and aesthetics. This technique provides resistance against corrosion, abrasion, and environmental elements, making it particularly useful in industries where both functionality and appearance are crucial. Lacquer-plated products often find applications in automotive parts, decorative items, and electronics, offering a combination of protective qualities and a polished finish.