Industrial Automations

Industrial automations revolutionize manufacturing processes, utilizing advanced technologies like PLCs (Programmable Logic Controllers) and robotics to enhance efficiency and precision. These systems streamline tasks such as assembly, packaging, and quality control, reducing manual labor and minimizing errors. With the integration of sensors and smart controls, industrial automations optimize production workflows, ensuring consistent output, and driving advancements in modern manufacturing across diverse industries.

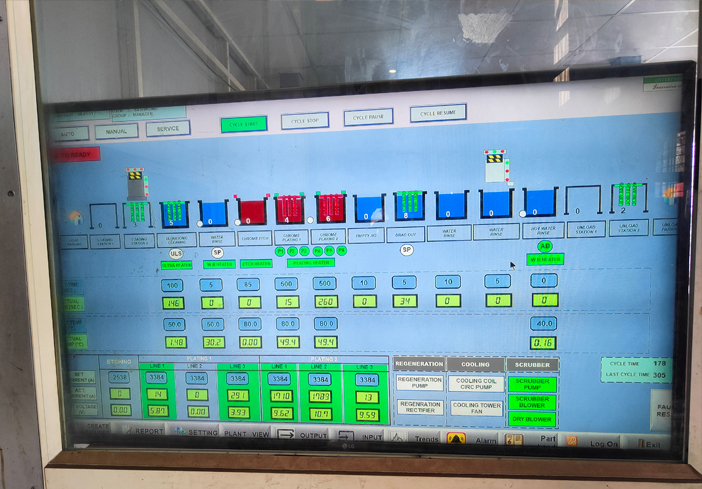

Scada

SCADA (Supervisory Control and Data Acquisition) is a powerful industrial control system that allows real-time monitoring and control of critical processes. Employed across various industries, SCADA systems enable operators to supervise, gather data, and make informed decisions remotely. With capabilities for data visualization, alarms, and process optimization, SCADA enhances operational efficiency and ensures the reliability of complex industrial processes, making it an integral component in modern industrial automation.

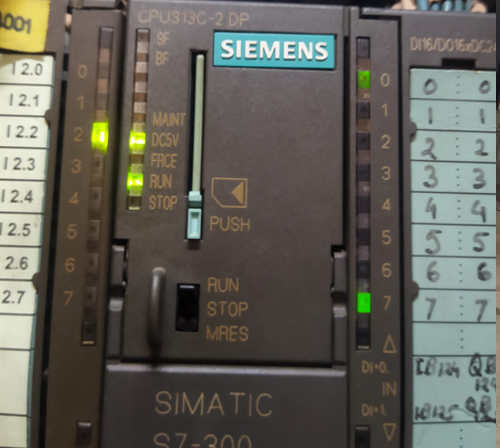

Plc programming

PLC (Programmable Logic Controller) programming is the art of creating sequences and instructions for PLCs, pivotal in automating industrial processes. Programmers use specialized languages to define logic, timing, and control functions, enabling the PLC to execute tasks with precision. This programming ensures seamless coordination among various components, optimizing efficiency and reliability in manufacturing and industrial automation. Skilled PLC programmers play a crucial role in developing robust control systems that enhance productivity and functionality across diverse industries.

IOT base programming

IoT (Internet of Things) based programming involves creating software to enable communication and data exchange among interconnected devices. Programmers use languages like Python or JavaScript to develop applications that facilitate seamless connectivity, data collection, and control within IoT ecosystems. This programming is essential for building smart systems that enhance efficiency, automate processes, and enable real-time monitoring across various industries, from smart homes to industrial automation.

Automation equipment’s

Automation equipment comprises a diverse range of machinery and devices designed to perform tasks with minimal human intervention. These advanced systems utilize technologies like PLCs, robotics, and sensors to streamline production processes in industries such as manufacturing and logistics. From robotic arms on assembly lines to conveyor systems and smart sensors, automation equipment enhances efficiency, accuracy, and overall productivity in modern industrial settings.

Electrical switchgears

Electrical switchgears are critical components in power distribution systems, ensuring the safe and controlled flow of electricity. These devices protect electrical circuits and equipment from overloads and faults. Comprising circuit breakers, fuses, and switches, switchgears play a pivotal role in maintaining electrical stability and reliability in residential, commercial, and industrial settings. Their design and functionality are integral to safeguarding electrical infrastructure and preventing damage during abnormal conditions, contributing to the overall safety and efficiency of power distribution networks.

Robotics

Robotics is a cutting-edge field that involves the design, construction, and operation of robots. These intelligent machines, equipped with sensors and programming, perform tasks autonomously or with minimal human intervention. In manufacturing, healthcare, and various industries, robotics enhances efficiency and precision, taking on roles from assembly line tasks to surgical procedures. As technology advances, robotics continues to redefine automation, contributing to safer and more efficient processes across diverse sectors.

SPM (special purpose machine)

Special Purpose Machines (SPM) are customized industrial machines designed to perform specific tasks with high precision and efficiency. Tailored to unique production requirements, these machines automate processes such as drilling, milling, or assembly, optimizing manufacturing workflows. SPMs enhance productivity by addressing specific needs in various industries, from automotive manufacturing to electronics. Their specialized design ensures cost-effective and streamlined production, contributing to overall operational excellence in specific manufacturing applications.

Leak testing machine

A Leak Testing Machine is a specialized device designed for the detection of leaks or defects in sealed products. Employed across industries like manufacturing, pharmaceuticals, and automotive, these machines use various methods such as pressure decay or vacuum testing to identify imperfections in airtight seals. Ensuring product quality and reliability, leak testing machines play a crucial role in maintaining stringent quality control standards, particularly in applications where airtightness is paramount.

Drilling & taping machine

A Drilling & Tapping Machine is a versatile industrial tool designed for precision drilling and tapping operations. Combining efficiency with accuracy, these machines are used in manufacturing processes, particularly in metalworking and fabrication. They automate the intricate tasks of creating holes and threads, streamlining production in industries ranging from automotive to aerospace. Drilling & Tapping Machines contribute to increased productivity and consistency in achieving precise dimensions across a variety of materials.

Boring Machine

A Boring Machine is a powerful tool in industrial machining, utilized for enlarging or refining existing holes in materials. With its precision and versatility, this machine is crucial in manufacturing processes across diverse industries. Boring machines are employed in creating accurate and consistent bores in materials like metal or wood, playing a key role in achieving the required specifications for components used in construction, automotive, and other sectors.

Valve end grinding machine

A Valve End Grinding Machine is an essential tool in the manufacturing of precision valves. This specialized machine is designed to grind and refine the ends of valves to ensure a precise fit and sealing. Widely used in industries such as automotive and oil and gas, the valve end grinding machine contributes to the production of high-performance valves, enhancing efficiency and reliability in critical applications.