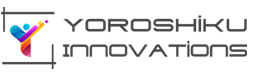

Plant Equipments

Plant equipment comprises a diverse array of machinery and tools designed for specific industrial functions. From cutting-edge technology to robust machinery, these equipment play a crucial role in manufacturing, processing, and production processes. Ranging from conveyor systems and CNC machines to boilers and precision instruments, plant equipment is tailored to meet the unique needs of various industries, ensuring efficiency, reliability, and optimal performance in the production environment.

Ced Anodes

CED (Cathodic Electro Deposition) anodes are essential components in the CED coating process, playing a pivotal role in electrochemical deposition. These anodes, often composed of materials like lead or lead alloys, facilitate the uniform application of protective coatings on metal substrates. By emitting a positive charge, CED anodes attract the negatively charged coating particles, ensuring a consistent, corrosion-resistant finish. These anodes are crucial in achieving high-quality, durable coatings in various industrial applications, including automotive and manufacturing.

Anode Memerane

An anode membrane is a crucial component in various electrochemical processes, particularly in fuel cells. Composed of advanced materials like proton exchange membranes (PEM), it facilitates the transport of ions, enabling efficient electrochemical reactions. Anode membranes play a key role in separating and conducting positively charged ions during energy conversion processes, contributing to the overall performance and efficiency of fuel cells used in applications ranging from clean energy production to portable electronic devices.

Bag Filter Systems

Bag filter systems are efficient air or liquid filtration solutions widely used in industrial settings. Comprising fabric filter bags within a housing, these systems effectively capture and remove particulate matter, dust, or pollutants. Employed in diverse industries such as manufacturing, pharmaceuticals, and energy production, bag filter systems ensure clean air or liquids, contributing to environmental compliance and process efficiency. Their modular design and high filtration efficiency make them essential for maintaining air quality and liquid purity in various applications.

Industrial RO,DM,plant

An Industrial Reverse Osmosis (RO) and Deionization (DM) plant is a sophisticated system designed for water treatment in industrial processes. Employing advanced filtration technologies, it removes impurities, minerals, and contaminants, ensuring high-purity water for various applications. Widely used in manufacturing, pharmaceuticals, and electronics, these plants enhance product quality and process efficiency by delivering purified water that meets stringent industry standards. The combination of RO and DM technologies ensures the production of ultra-pure water, vital for diverse industrial processes where water quality is paramount.

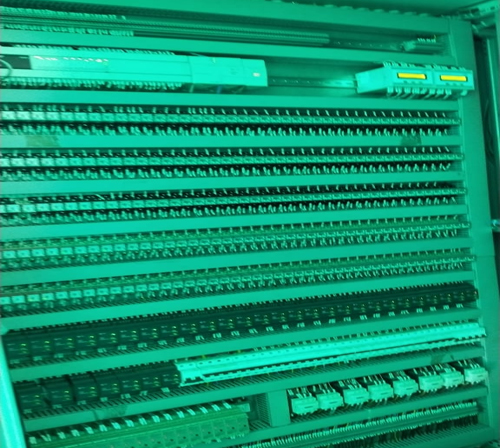

Plc control panel

A PLC (Programmable Logic Controller) Control Panel is a central component in industrial automation, housing the PLC that orchestrates and regulates machinery and processes. These panels feature a user-friendly interface for programming and monitoring, facilitating seamless control over diverse equipment. Essential in manufacturing, energy, and process industries, PLC control panels streamline operations, enhance efficiency, and contribute to the precision and reliability of automated systems, ensuring optimal performance and adherence to specific operational parameters.

Electroplating filters

Electroplating filters are integral components in electroplating systems, designed to purify plating solutions by removing contaminants and impurities. These filters play a crucial role in ensuring a consistently high-quality plating process. By efficiently trapping particles and maintaining solution cleanliness, electroplating filters contribute to the production of flawless plated surfaces in various industries, including automotive, electronics, and manufacturing. Their reliable filtration capabilities enhance the overall efficiency and performance of electroplating processes, delivering optimal results.

Transporter wagon & accessories

Transporter wagons and accessories are essential elements in material handling and logistics. Designed for efficient movement of goods within industrial facilities, these wagons feature sturdy construction and versatile accessories such as rails, ramps, and lifting mechanisms. They play a pivotal role in streamlining intra-facility transport, ensuring smooth operations in warehouses, manufacturing plants, and distribution centers. With a focus on durability and functionality, transporter wagons and accessories contribute to the seamless flow of materials, enhancing productivity and optimizing logistical processes.

Pp/ms/ss/pvc/frp process tanks

PP/MS/SS/PVC/FRP process tanks are versatile industrial vessels designed for various applications. Constructed from materials like polypropylene, mild steel, stainless steel, PVC, or fiberglass-reinforced plastic, these tanks cater to diverse processing needs. Their robust build ensures resistance to corrosion, chemicals, and extreme conditions, making them ideal for applications in industries such as chemical processing, water treatment, and manufacturing. These tanks offer durability, longevity, and compatibility with a range of substances, providing reliable solutions for diverse industrial processes.

Ultrafiltration systems

Ultrafiltration systems are advanced water treatment solutions utilizing semi-permeable membranes to effectively filter out impurities, bacteria, and particles from liquids. Widely employed in industrial processes, these systems deliver high-purity water by selectively allowing only specific molecules to pass through. With applications in wastewater treatment, food and beverage industries, and more, ultrafiltration systems provide a reliable and efficient means of ensuring water quality, contributing to environmental sustainability and process optimization.

Manual barrel

A manual barrel is a versatile industrial container designed for various material handling and storage needs. With a user-operated mechanism, these barrels provide ease of use in loading, unloading, and transportation of goods. Commonly used in manufacturing, agriculture, and logistics, manual barrels come in diverse materials, sizes, and configurations, ensuring compatibility with different industries and applications. Their robust construction and ergonomic design make them essential for manual handling tasks, contributing to operational efficiency across various sectors.

Manual dryer

A manual dryer is an efficient and user-operated drying solution for diverse applications. Designed for simplicity and ease of use, it requires manual loading and unloading of items. Commonly used in small-scale operations or specialized settings, manual dryers provide a cost-effective way to remove moisture from various materials. With customizable settings and compact designs, these dryers offer flexibility for drying processes in industries such as textiles, food, and research, where manual control is preferred.

IGBT& Oil cooled rectifier

An IGBT (Insulated Gate Bipolar Transistor) and oil-cooled rectifier is a sophisticated electrical system essential in various industrial applications. It combines the efficiency of IGBT technology with an oil-cooling mechanism, ensuring optimal performance and reliability in power rectification. Widely used in processes such as electroplating and electrochemical applications, this system provides precise control and stable power output. Its design ensures efficient heat dissipation, making it suitable for demanding industrial environments where reliable rectification is critical for operational success.

Chiller unit with cooling tower

A chiller unit with a cooling tower is an integrated cooling system designed for efficient temperature regulation in industrial processes. This setup combines the chilling capabilities of a chiller unit with the evaporative cooling provided by a cooling tower. Ideal for applications such as air conditioning, manufacturing, and data centers, this system ensures optimal temperature control, energy efficiency, and cost-effectiveness, making it a versatile solution for various cooling needs in industrial settings